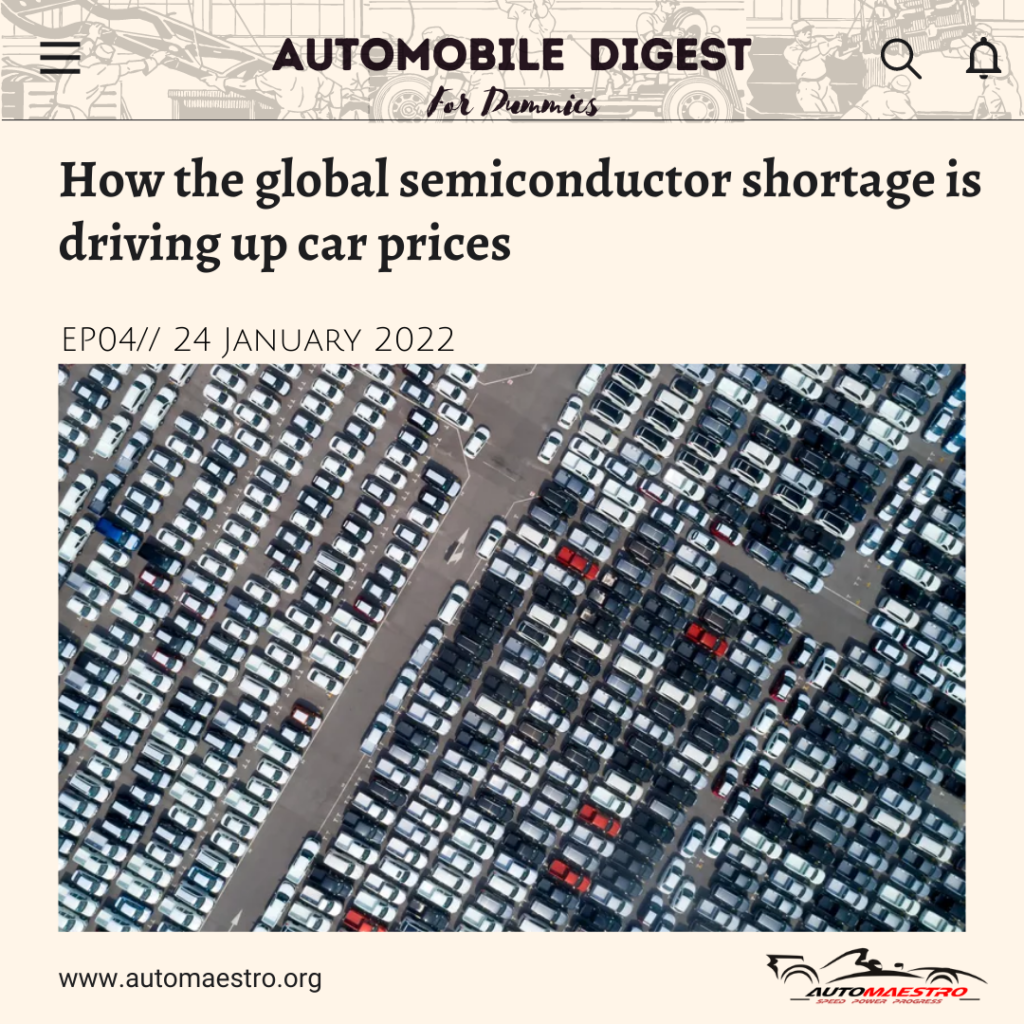

A modern car can contain over a thousand microchips, vital for key functions like ignition and engine control. Thanks to their lower cost, cars use old “legacy” chips – from which chip manufacturers receive a relatively narrow profit margin.

To meet the surge in demand for use in semiconductor-based electronics during the pandemic, chip makers used more of their production capacity to make upper-tier, more profitable chips, dwindling their availability for car makers.

Even after the ease of Covid-19 restrictions when demand for vehicles are recovering, car makers are simply not receiving enough microchips to meet the demand, thus forcing them to either slow down production, or remove features reliant on semiconductors. Of course, buyers are paying the price owing to higher price tags.

With tens of thousands of already-built vehicles waiting for chips on parking lots outside their factories, the global semiconductor shortage is estimated to have cost over $200B for car makers in lost revenue last year, and the market is not expected to fully recover for at least another couple of years.